Automated Test Equipment

Automated Test Equipment (ATE) is one of the vital production assets for manufacturing enterprises. ATE enables production houses to conduct production testing faster than manual testing, saving millions in terms of time, cost, and resources. Automated Test Equipment is widely used in product testing (Hardware and Software), PCB Testing, Functional Testing, Performance Testing, Environmental Parameter Testing, etc. in various domains. An ATE is reliable and consistent, and help users considerably minimize testing time. ATE provides a high degree of repeatability and speed with minimal, or no error compared to manual testing.

Mistral designs and develops Automated Test Equipment for application-specific product testing and validation. The Test Automation and ATE offerings include Test Jig (specialized hardware) development, Integration of ATE equipment, and ATE software development. Mistral can build and supply Automated Test Equipment for testing a range of systems and subsystems that are part of Radars, Sonars, Aircraft, ships, submarines, consumer electronics, medical devices, industrial platforms, etc.

Mistral designs and develops Automated Test Equipment for application-specific product testing and validation. The Test Automation and ATE offerings include Test Jig (specialized hardware) development, Integration of ATE equipment, and ATE software development. Mistral can build and supply Automated Test Equipment for testing a range of systems and subsystems that are part of Radars, Sonars, Aircraft, ships, submarines, consumer electronics, medical devices, industrial platforms, etc.

ATE Design and Development

Mistral has over 25 years of experience providing cutting-edge embedded solutions for Aerospace and Defence, Industrial, Wearable, Automotive and Healthcare applications. Our unparalleled expertise in the embedded domain enables us to design and develop ATEs that cater to the critical needs of testing systems at any level of complexity. Our Automated Test Equipment solutions reduce the overall testing time by up to 75%, enabling product developers to deploy their resources for core development activities more efficiently. The ATE Design and Development ensures integration as per the IPC standards while the cable harness complies with EMC standard and IPC-620.

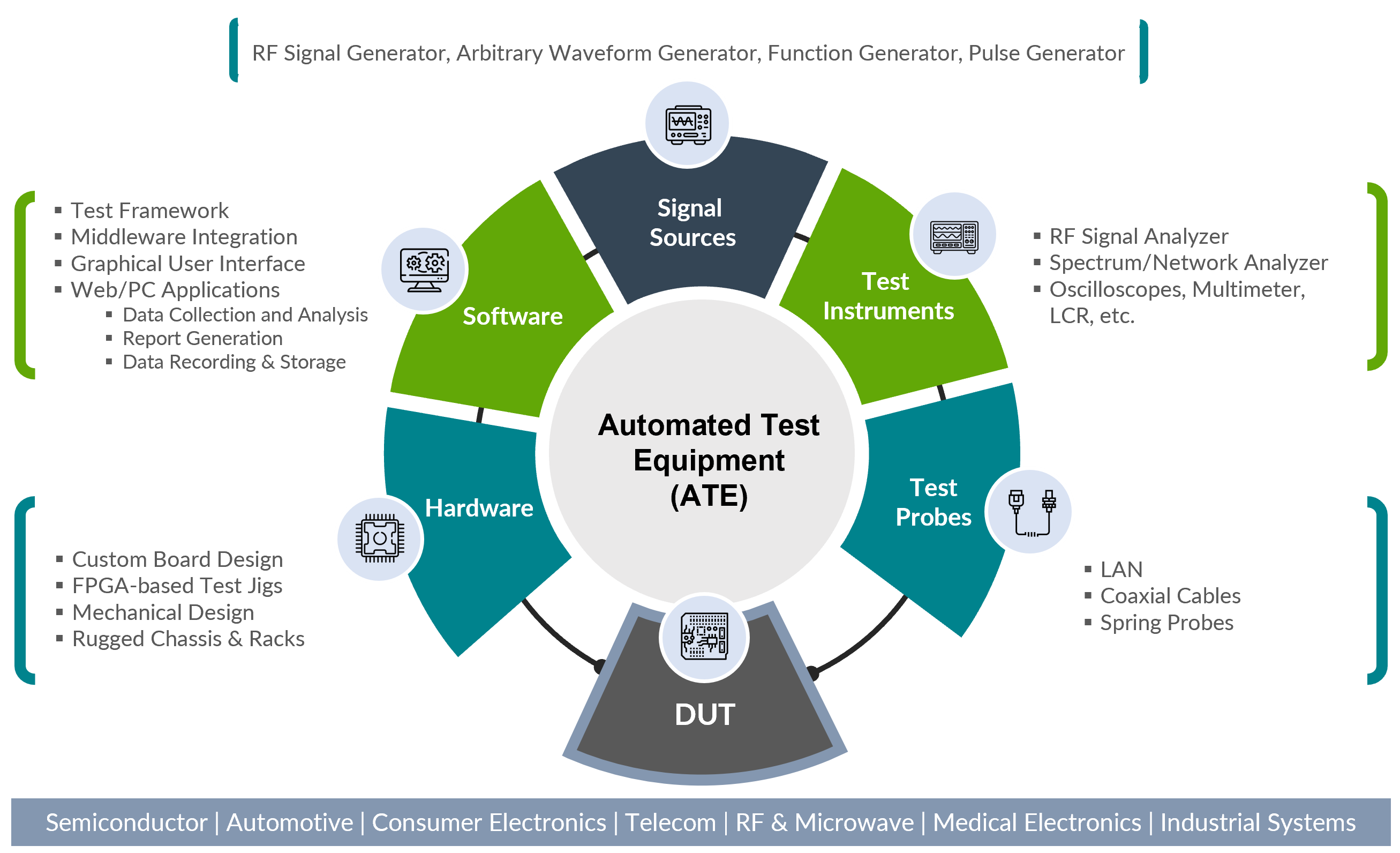

Typically, Automated Test Equipment Design consist of Smart Fixtures, Chambers, Rackmount Servers, Workstations, Matrix Switches and Controllers, I/O Units, Test Instruments (Oscilloscopes, Spectrum Analyzers, Multimeters, etc.), RF Signal Sources (Signal Generators, Arbitrary Waveform Generators, Function Generators, Pulse Generators, etc.), Test Probes and the Test Framework among others. ATE aids testing of memory, digital signals, mixed signals, system-on-a-chip (SoC) components and range of other functional and technical aspects of the Device Under Test (DUT). The system provides multiple USB Hubs and Ethernet ports to interface with DUT and the Host PC. ATE is ideal for pre-production and post-production testing of various functional, performance and Environmental parameters of the DUT. Our ATE Design and Development services include BOM Analysis, Sourcing of Components, Custom hardware development, Rack/Chassis manufacturing, cable harness, system integration, Test suite development and integration.

ATE Test Jig Development

One of the key aspects of Automated Test Equipment is ATE Test Jig Development. With end-to-end hardware (including RF), software, mechanical design and system integration expertise, Mistral is in best position to build Test Jigs for any complex systems. Our team of hardware and software experts specialize in creating high-quality and efficient ATE Test Jig Development tailored to specific application needs. Our solutions are designed to streamline and optimize the testing process, improve productivity, and ensure precise measurements.

One of the key aspects of Automated Test Equipment is ATE Test Jig Development. With end-to-end hardware (including RF), software, mechanical design and system integration expertise, Mistral is in best position to build Test Jigs for any complex systems. Our team of hardware and software experts specialize in creating high-quality and efficient ATE Test Jig Development tailored to specific application needs. Our solutions are designed to streamline and optimize the testing process, improve productivity, and ensure precise measurements.

ATE Test Frameworks

Mistal offers custom ATE Test Frameworks for user-specific applications. The ATE Test Frameworksand test suites are developed using a variety of software packages. For example, Python based test automation using PyVisa package, a variety of programming languages including Python, C#, etc., and run on Windows and Linux PCs (Host). The Test suites enable users to manage data collection, storage, report generation and post analysis. The ATE Test Frameworks provide a Command Line Interface and a GUI for test management. The Test framework can support multiple channels (based on test needs) in one cycle without changing the test setup. The ATE Test Frameworks aid configuration of various T&M instruments and the Device Under Test (DUT), in addition to the execution of test cases such as Functional, Performance and Environmental parameters.

Mistral’s ATE Designs aid the users to automatically generate final test reports in a format (Excel, .CSV, PDF) of their choice with Logs. These reports are ready-to-print and can be used for Product Certification.

Mistral designs and integrates simple and intuitive User Interfaces (UI) that help the users to monitor and configure the ATE and DUT. The UI is designed in consultation with the users, capturing customer/application-specific needs. Our two decades of experience developing sophisticated embedded, PC and Web applications enables us to develop and integrate UI Apps with optimal performance and low-latency data management. Mistral can develop ATEs for Defense Subsystems (Radar Modules, Transmit-Receive Modules, RF Systems, Data Recorders, Digital Receivers, Radar Controllers, Signal Processors, etc.), Semiconductor fabrication, Consumer electronics, Telecommunication Equipment and Medical technology Products, among others! Mistral can provide Automated Test Equipment Design services for Generic Test, Acceptance Test, Environmental Test, Vibration Test, Mission Computer Test, Auto Pilot Test, Radar Processing Unit Test, and Missile Test among others.

Mistral designs and integrates simple and intuitive User Interfaces (UI) that help the users to monitor and configure the ATE and DUT. The UI is designed in consultation with the users, capturing customer/application-specific needs. Our two decades of experience developing sophisticated embedded, PC and Web applications enables us to develop and integrate UI Apps with optimal performance and low-latency data management. Mistral can develop ATEs for Defense Subsystems (Radar Modules, Transmit-Receive Modules, RF Systems, Data Recorders, Digital Receivers, Radar Controllers, Signal Processors, etc.), Semiconductor fabrication, Consumer electronics, Telecommunication Equipment and Medical technology Products, among others! Mistral can provide Automated Test Equipment Design services for Generic Test, Acceptance Test, Environmental Test, Vibration Test, Mission Computer Test, Auto Pilot Test, Radar Processing Unit Test, and Missile Test among others.

EXPERTISE

Mistral provides comprehensive, end-to-end solutions for the design, development, and integration of Automated Test Equipment (ATE). Our services cover the entire spectrum, including system architecture, hardware design, test framework development, test case creation, Test Application Suite (TAS) development, system engineering, installation support, and training. From conceptualization to implementation, Mistral is your trusted partner for reliable ATE solutions and Test Automation. We help you optimize your testing processes and enhance your product quality with our cutting-edge ATE design and development services.

Hardware & FPGA Design for Test Jig

- Custom hardware development

- Custom backplane design and integration

- Custom FPGA Boards

- Power efficient FPGA designs

- Networking, Routing, Storage Management

- Thermal Management

System Integration

- System Architecture Design

- Custom, rugged ATE Chassis for diverse operating conditions

- Integration of multi-vendor Test and Measurement Instruments and custom Hardware development

- Integration of Test Framework and system performance testing

- EMI/EMC and Environmental Qualification

- Training, Support and Product Sustenance

Software and Test Framework

- Test Framework Development

- Data acquisition, Management, Storage and Report Generation

- Qt/QML, SWIFT, PHP/Python, Android, iOS, Cordova, .NET, C#

- Thermal Management

Application Development

- Easy to use, creative and intuitive applications

- Multi-platform HMI framework development

- Data acquisition, Management, Storage and Report Generation

- Android based touch display systems

- Custom Widgets development

- Qt/QML, SWIFT, PHP/Python, Android, iOS, Cordova, .NET, C#

Industrial Design

- Rugged enclosure designs

- 3D CAD modelling and design

- Rugged system Design

- Thermal Management and EMI/EMC shielding

- Air flow-through / Conduction-cooled

- Forced air conduction-cooled

- Environmental, shock, vibration

Production Support

- BOM Analysis

- Procurement of BOM

- Custom Hardware Design and Development

- Test Suite Development and Integration

- Design and Development of rack/chassis

- Cable Assembly

- System integration

APPLICATIONS

Aerospace and Defense

ATE plays a critical role in ensuring the reliability and performance of aerospace and defense systems. ATE enables efficient and precise testing of components and systems, aiding in quality control, validation, and compliance with stringent industry standards.

Medical Electronics

ATE is vital for ensuring the safety and effectiveness of medical electronics. They enable comprehensive testing of medical devices and electronic sub-systems, ensuring compliance with regulatory standards and delivering reliable healthcare solutions.

Automotive Electronics

ATE is essential for the quality and performance testing of automotive electronics. ATE systems enable thorough testing of components like ECUs, sensors, and infotainment systems, ensuring reliability, functionality, and adherence to automotive industry standards.

Drone Electronics

ATE plays a crucial role in the testing and validation of drone electronics. ATE is ideal for the comprehensive testing of flight controllers, sensors, communication modules, and power systems, ensuring reliable and safe operation of drones in various applications.

Industrial Systems

ATE aids in ensuring the performance and reliability of industrial systems and products. They enable efficient testing of components, control systems, and machinery, facilitating quality control, troubleshooting, and compliance with industrial standards and regulations.

Wearable Electronics

ATE is essential to functionality and performance testing of wearable electronics. ATE aids comprehensive testing of sensors, battery life, connectivity, and user interface, ensuring the quality and reliability of wearable devices in diverse applications.

Block Diagram

End-to-end design, development, and integration of Automated Test Equipment